Many sectors of the lighting market are saturated with bottom-dollar, discount bin LED fixtures. These products are built to be at the lowest possible cost, using inexpensive components to keep your price low.

The word “inexpensive” may be a little generous. A lot of these products are just cheap. Cheap in price, cheaply made – and most importantly to the consumer, cheap in quality. It’s a cliché, but the old adage “you get what you pay for” can certainly apply to light fixtures.

One of the many issues with these cheap fixtures is that they are built to be disposable. Planned obsolescence. Wasteful.

At LumenFocus, we don’t believe in using inferior components. The better the ingredients, the better the recipe. Sure, we try to keep costs as low as possible to give you the best prices we can. But sacrificing quality is where we draw the line. Our products are designed to be the best combination of efficiency and economy – we want to give you the best bang for your buck.

Many of the cheaper products in the marketplace utilize components from suppliers you probably have never heard of. Let’s say you purchased one of these fixtures, and a few months later, an LED board stops illuminating:

- Can you even repair it, or do you have to buy a completely new fixture?

- If you are able to repair it, how difficult is it? A lot of cheaper fixtures use some kind of glue or tape to affix the boards, which can be quite irritating to remove.

- Who do you contact for replacement?

- Does your warranty cover this failure, and who do you contact regarding a warranty claim?

- Even if you’re able to remove and replace the problematic LED module, can you replace it with a more established brand?

- How do you know if another brand is compatible? Will it even fit? Will the light output and CCT match the other fixtures?

- How do you get answers? Does the fixture manufacturer have a customer service department in the US?

So swapping out these boards could be a pain. But the fixtures are super cheap – so what the heck, you can just buy a new fixture. Three weeks later, the board goes out in another fixture. Rinse and repeat.

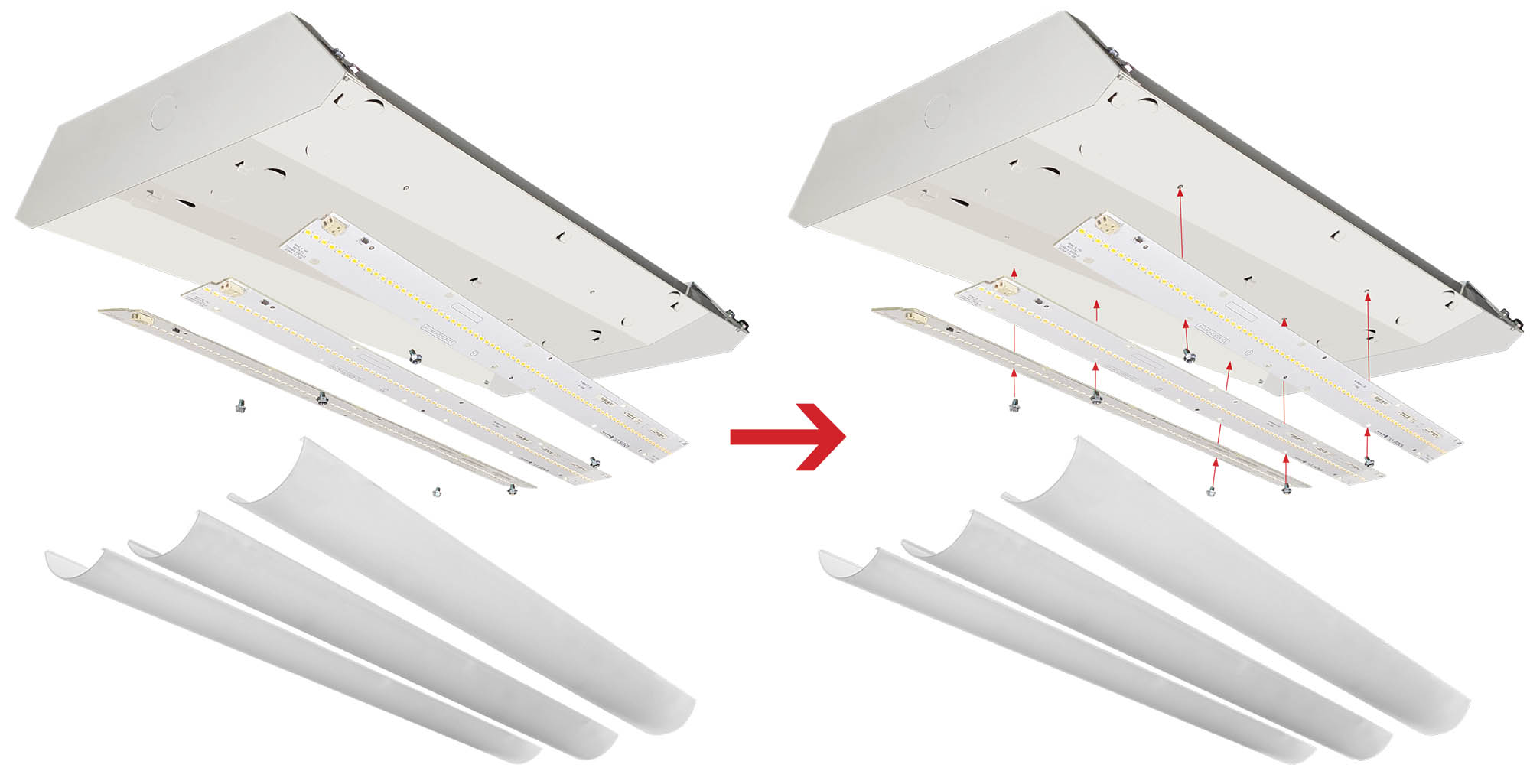

What if you bought some LumenFocus PBLs instead? They may have been a little more expensive up front, but they’re probably at least 30 percent more efficient. Board and driver failures on these are very rare, and our predicted lifetimes are extremely long (L70 greater than 188,000 calculated hours, and L90 greater than 60,000 hours on the G2 series). But what if you have a bad board? Accessing our boards takes just a minute or two – if you have lensed PBLs, pop off the lens, remove a few screws and pull out a few wires and you have the board in your hands. See below:

In the rare event you have a board or driver failure in the field, contact our factory in North Carolina and we can ship a replacement your way in no time. We also have technical support on staff here every day to assist with any questions you may have.

The same goes for any of the fabricated elements of the fixture – the housing, end caps, etc. Let’s say someone clipped the edge of a PBL with a raised fork lift in the field. We can get you a replacement end cap quickly, and it’ll affix right into place with a few screws and a quarter turn.

A similar story can be told about recessed troffers. Many of the discount imported products are made extremely cheaply. Fixture failures can be such a pain. Many imported flat panels, for example, cannot be repaired, only replaced.

While our FormFocus units are pretty much guaranteed to outlast flat panels, it’s possible (though rare) you could run into a board failure in the future. A board failure in one of our FormFocus units requires a screwdriver/drill, an awl, a ladder, and a few of minutes of your time.

Our fixtures require very little maintenance throughout their lifetimes. We have specifically engineered these products in a way that, when you do have to perform maintenance, the task is quick and simple. We want our products to be repairable and upgradeable.

We’ve adopted a concept we call Re-boardABILITY (which you can read more about here). With Re-boardABILITY, you won’t get stuck with obsolete fixtures. LEDs are going to continue to get more and more efficient. Re-boardABILITY gives you a path to have the most efficient boards in your fixtures. This wouldn’t apply to many of the cheap, disposable products in the market.

VIDEO: FFR 2×4 Re-boardABILITY demonstration

VIDEO: PBL Re-boardABILITY demonstration

The repairability of our fixtures extends past the fabricated components and LED light engines. It covers controls as well. If you have a sensor failure, we can get you a replacement quickly. We only use the best controls vendors – Legrand, Leviton, Enlighted, Philips, etc. Even if it’s a sensor we don’t have in stock, we’ll get it drop-shipped from our vendor straight to you.

The combination of repairability, Re-boardABILITY, and sustainable, upgradeable controls with our already highly efficient LED fixtures further adds to their longevity and stature in the marketplace.

Don’t settle for the rubbish that’s out there. Invest in a quality lighting system. It will pay off in the end.