LED Vaportight High Bay

The Altor series is designed for the high demands of food and meat industry facilities. The unique design is bacteria and debris resistant, easy to clean, and features a true water seal. The housing is made of UL 5VA fiberglass and will not melt or burn. The Altor WVLF G2 is available in 2-foot (WVLF G2 2) and 4-foot (WVLF G2 4) options, with multiple lumen output packages, color temperatures and hanging options. The high efficacy LED boards in the WVLF G2 are rated at 90+ CRI. The Altor series also includes the narrow profile NVLF G2 (learn more about the NVLF G2 here). Every WVLF G2 is made in the USA - in our Henderson, NC facility, utilizing mostly domestic and some foreign components.

- Applications: Designed for food and meat processing facilities, or other applications that have similar requirements of a vaportight luminaire. Also suitable for most industrial, retail and recreational low bay and high bay applications - warehouse, manufacturing facility, freezer, gymnasium

- Lumen Output: From 7,700 in the 2-foot version up to 23,600+ in the 4-foot version

- Max Lumens Per Watt: 144.6

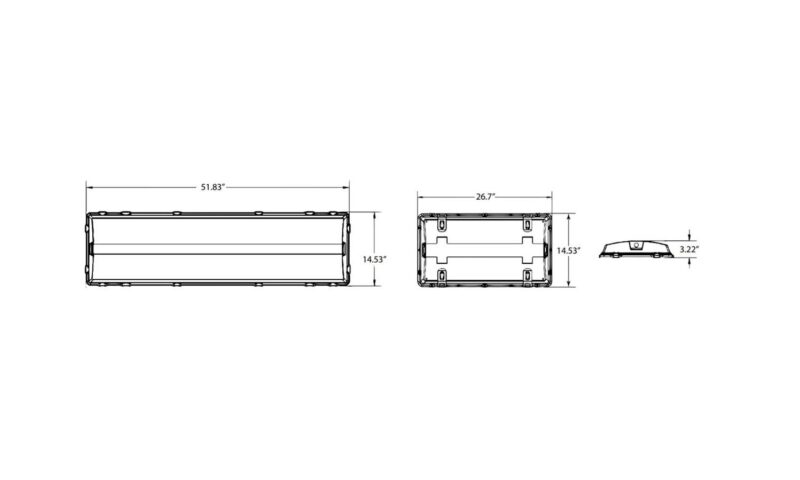

- Size Options: 2-foot (WVLF G2 2) and 4-foot (WVLF G2 4)

- Predicted L70 Lifetime: ≥131,000 hours for WVLF G2 2 (calculated); ≥129,000 hours for WVLF G2 4 (calculated);

- Warranty: 5 year limited system warranty

- Certifications: UL 1598 listed for US and Canada, suitable for wet locations. Other certifications: NSF, IP66, RoHS, NEMA 4X, PSI 1500

- Made in the USA, in our Henderson, NC facility, utilizing mostly domestic and some foreign components. BAA compliant options are available

| Size | Lumens | Watts | LPW | CRI / Color Temp | Shielding | Voltages Available | Predicted L70 Lifetime | |

|---|---|---|---|---|---|---|---|---|

| WVL F G2 2 VL UV CFP 930 | 2-foot | 7,734.50 | 55.7 | 138.8 | 90 CRI / 3000K | Clear flat polycarbonate | 120-277V, 347V, 480V | Greater or equal to 131,000 hours (calculated) |

| WVL F G2 2 VL UV CFP 935 | 2-foot | 7,767.10 | 55.7 | 139.4 | 90 CRI / 3000K | Clear flat polycarbonate | 120-277V, 347V, 480V | Greater or equal to 131,000 hours (calculated) |

| WVL F G2 2 VL UV CFP 940 | 2-foot | 7,951.60 | 55.7 | 142.7 | 90 CRI / 3000K | Clear flat polycarbonate | 120-277V, 347V, 480V | Greater or equal to 131,000 hours (calculated) |

| WVL F G2 2 VL UV CFP 950 | 2-foot | 7,951.60 | 55.7 | 142.7 | 90 CRI / 3000K | Clear flat polycarbonate | 120-277V, 347V, 480V | Greater or equal to 131,000 hours (calculated) |

| WVL F G2 2 LW UV CFP 930 | 2-foot | 11,569.00 | 82.6 | 140.1 | 90 CRI / 3000K | Clear flat polycarbonate | 120-277V, 347V, 480V | Greater or equal to 131,000 hours (calculated) |

| WVL F G2 2 LW UV CFP 935 | 2-foot | 11,617.70 | 82.6 | 140.7 | 90 CRI / 3500K | Clear flat polycarbonate | 120-277V, 347V, 480V | Greater or equal to 131,000 hours (calculated) |

| WVL F G2 2 LW UV CFP 940 | 2-foot | 11,893.70 | 82.6 | 144.1 | 90 CRI / 4000K | Clear flat polycarbonate | 120-277V, 347V, 480V | Greater or equal to 131,000 hours (calculated) |

| WVL F G2 2 LW UV CFP 950 | 2-foot | 11,893.70 | 82.6 | 144.1 | 90 CRI / 5000K | Clear flat polycarbonate | 120-277V, 347V, 480V | Greater or equal to 131,000 hours (calculated) |

| WVL F G2 2 MD UV CFP 930 | 2-foot | 15,469.00 | 111.5 | 138.8 | 90 CRI / 3000K | Clear flat polycarbonate | 120-277V, 347V, 480V | Greater or equal to 131,000 hours (calculated) |

| WVL F G2 2 MD UV CFP 935 | 2-foot | 15,534.20 | 111.5 | 139.4 | 90 CRI / 3500K | Clear flat polycarbonate | 120-277V, 347V, 480V | Greater or equal to 131,000 hours (calculated) |

| WVL F G2 2 MD UV CFP 940 | 2-foot | 15,903.10 | 111.5 | 142.7 | 90 CRI / 4000K | Clear flat polycarbonate | 120-277V, 347V, 480V | Greater or equal to 131,000 hours (calculated) |

| WVL F G2 2 MD UV CFP 950 | 2-foot | 15,903.10 | 111.5 | 142.7 | 90 CRI / 5000K | Clear flat polycarbonate | 120-277V, 347V, 480V | Greater or equal to 131,000 hours (calculated) |

| WVL F G2 2 HI UV CFP 930 | 2-foot | 18,022.60 | 127.3 | 141.6 | 90 CRI / 3000K | Clear flat polycarbonate | 120-277V, 347V, 480V | Greater or equal to 131,000 hours (calculated) |

| WVL F G2 2 HI UV CFP 935 | 2-foot | 18,098.60 | 127.3 | 142.2 | 90 CRI / 3500K | Clear flat polycarbonate | 120-277V, 347V, 480V | Greater or equal to 131,000 hours (calculated) |

| WVL F G2 2 HI UV CFP 940 | 2-foot | 18,528.50 | 127.3 | 145.5 | 90 CRI / 4000K | Clear flat polycarbonate | 120-277V, 347V, 480V | Greater or equal to 131,000 hours (calculated) |

| WVL F G2 2 HI UV CFP 950 | 2-foot | 18,528.50 | 127.3 | 145.5 | 90 CRI / 5000K | Clear flat polycarbonate | 120-277V, 347V, 480V | Greater or equal to 131,000 hours (calculated) |

| WVL F G2 4 VL UV CFP 930 | 4-foot | 15,469.00 | 111.5 | 138.8 | 90 CRI / 3000K | Clear flat polycarbonate | 120-277V, 347V, 480V | Greater or equal to 129,000 hours (calculated) |

| WVL F G2 4 VL UV CFP 935 | 4-foot | 15,534.20 | 111.5 | 139.4 | 90 CRI / 3500K | Clear flat polycarbonate | 120-277V, 347V, 480V | Greater or equal to 129,000 hours (calculated) |

| WVL F G2 4 VL UV CFP 940 | 4-foot | 15,903.10 | 111.5 | 142.7 | 90 CRI / 4000K | Clear flat polycarbonate | 120-277V, 347V, 480V | Greater or equal to 129,000 hours (calculated) |

| WVL F G2 4 VL UV CFP 950 | 4-foot | 15,903.10 | 111.5 | 142.7 | 90 CRI / 5000K | Clear flat polycarbonate | 120-277V, 347V, 480V | Greater or equal to 129,000 hours (calculated) |

| WVL F G2 4 LW UV CFP 930 | 4-foot | 19,201.80 | 136.6 | 140.6 | 90 CRI / 3000K | Clear flat polycarbonate | 120-277V, 347V, 480V | Greater or equal to 129,000 hours (calculated) |

| WVL F G2 4 LW UV CFP 935 | 4-foot | 19,282.80 | 136.6 | 141.2 | 90 CRI / 3500K | Clear flat polycarbonate | 120-277V, 347V, 480V | Greater or equal to 129,000 hours (calculated) |

| WVL F G2 4 LW UV CFP 940 | 4-foot | 19,740.70 | 136.6 | 144.6 | 90 CRI / 4000K | Clear flat polycarbonate | 120-277V, 347V, 480V | Greater or equal to 129,000 hours (calculated) |

| WVL F G2 4 LW UV CFP 950 | 4-foot | 19,740.70 | 136.6 | 144.6 | 90 CRI / 5000K | Clear flat polycarbonate | 120-277V, 347V, 480V | Greater or equal to 129,000 hours (calculated) |

| WVL F G2 4 MD UV CFP 930 | 4-foot | 23,028.00 | 169.3 | 136 | 90 CRI / 3000K | Clear flat polycarbonate | 120-277V, 347V, 480V | Greater or equal to 129,000 hours (calculated) |

| WVL F G2 4 MD UV CFP 935 | 4-foot | 23,125.10 | 169.3 | 136.6 | 90 CRI / 3500K | Clear flat polycarbonate | 120-277V, 347V, 480V | Greater or equal to 129,000 hours (calculated) |

| WVL F G2 4 MD UV CFP 940 | 4-foot | 23,674.30 | 169.3 | 139.8 | 90 CRI / 4000K | Clear flat polycarbonate | 120-277V, 347V, 480V | Greater or equal to 129,000 hours (calculated) |

| WVL F G2 4 MD UV CFP 950 | 4-foot | 23,674.30 | 169.3 | 139.8 | 90 CRI / 5000K | Clear flat polycarbonate | 120-277V, 347V, 480V | Greater or equal to 129,000 hours (calculated) |

| Equivalency* | |

|---|---|

| WVL F G2 2 VL UV CFP 930 | 150W MH |

| WVL F G2 2 VL UV CFP 935 | 150W MH |

| WVL F G2 2 VL UV CFP 940 | 150W MH |

| WVL F G2 2 VL UV CFP 950 | 150W MH |

| WVL F G2 2 LW UV CFP 930 | 250W MH / 3L F54 T5HO / 4L F32 T8, HBF |

| WVL F G2 2 LW UV CFP 935 | 250W MH / 3L F54 T5HO / 4L F32 T8, HBF |

| WVL F G2 2 LW UV CFP 940 | 250W MH / 3L F54 T5HO / 4L F32 T8, HBF |

| WVL F G2 2 LW UV CFP 950 | 250W MH / 3L F54 T5HO / 4L F32 T8, HBF |

| WVL F G2 2 MD UV CFP 930 | 400W MH / 4L F54 T5HO / 6L F32 T8, HBF |

| WVL F G2 2 MD UV CFP 935 | 400W MH / 4L F54 T5HO / 6L F32 T8, HBF |

| WVL F G2 2 MD UV CFP 940 | 400W MH / 4L F54 T5HO / 6L F32 T8, HBF |

| WVL F G2 2 MD UV CFP 950 | 400W MH / 4L F54 T5HO / 6L F32 T8, HBF |

| WVL F G2 2 HI UV CFP 930 | 400W PSMH |

| WVL F G2 2 HI UV CFP 935 | 400W PSMH |

| WVL F G2 2 HI UV CFP 940 | 400W PSMH |

| WVL F G2 2 HI UV CFP 950 | 400W PSMH |

| WVL F G2 4 VL UV CFP 930 | 400W MH |

| WVL F G2 4 VL UV CFP 935 | 400W MH |

| WVL F G2 4 VL UV CFP 940 | 400W MH |

| WVL F G2 4 VL UV CFP 950 | 400W MH |

| WVL F G2 4 LW UV CFP 930 | 400W PSMH / 5L F54 T5HO |

| WVL F G2 4 LW UV CFP 935 | 400W PSMH / 5L F54 T5HO |

| WVL F G2 4 LW UV CFP 940 | 400W PSMH / 5L F54 T5HO |

| WVL F G2 4 LW UV CFP 950 | 400W PSMH / 5L F54 T5HO |

| WVL F G2 4 MD UV CFP 930 | 6L F54 T5HO |

| WVL F G2 4 MD UV CFP 935 | 6L F54 T5HO |

| WVL F G2 4 MD UV CFP 940 | 6L F54 T5HO |

| WVL F G2 4 MD UV CFP 950 | 6L F54 T5HO |

| Image | Spec Sheet | .ies & .pdf files | |

|---|---|---|---|

| WVL F G2 2 VL UV CFP 930 | View | Download | Contact Factory |

| WVL F G2 2 VL UV CFP 935 | View | Download | Contact Factory |

| WVL F G2 2 VL UV CFP 940 | View | Download | Contact Factory |

| WVL F G2 2 VL UV CFP 950 | View | Download | Contact Factory |

| WVL F G2 2 LW UV CFP 930 | View | Download | Contact Factory |

| WVL F G2 2 LW UV CFP 935 | View | Download | Contact Factory |

| WVL F G2 2 LW UV CFP 940 | View | Download | Contact Factory |

| WVL F G2 2 LW UV CFP 950 | View | Download | Contact Factory |

| WVL F G2 2 MD UV CFP 930 | View | Download | Contact Factory |

| WVL F G2 2 MD UV CFP 935 | View | Download | Contact Factory |

| WVL F G2 2 MD UV CFP 940 | View | Download | Contact Factory |

| WVL F G2 2 MD UV CFP 950 | View | Download | Contact Factory |

| WVL F G2 2 HI UV CFP 930 | View | Download | Contact Factory |

| WVL F G2 2 HI UV CFP 935 | View | Download | Contact Factory |

| WVL F G2 2 HI UV CFP 940 | View | Download | Contact Factory |

| WVL F G2 2 HI UV CFP 950 | View | Download | Contact Factory |

| WVL F G2 4 VL UV CFP 930 | Download | Contact Factory | |

| WVL F G2 4 VL UV CFP 935 | Download | Contact Factory | |

| WVL F G2 4 VL UV CFP 940 | Download | Contact Factory | |

| WVL F G2 4 VL UV CFP 950 | Download | Contact Factory | |

| WVL F G2 4 LW UV CFP 930 | Download | Contact Factory | |

| WVL F G2 4 LW UV CFP 935 | Download | Contact Factory | |

| WVL F G2 4 LW UV CFP 940 | Download | Contact Factory | |

| WVL F G2 4 LW UV CFP 950 | Download | Contact Factory | |

| WVL F G2 4 MD UV CFP 930 | Download | Contact Factory | |

| WVL F G2 4 MD UV CFP 935 | Download | Contact Factory | |

| WVL F G2 4 MD UV CFP 940 | Download | Contact Factory | |

| WVL F G2 4 MD UV CFP 950 | Download | Contact Factory |

Ideal for food and meat processing

The Altor WVLF G2 is bacteria and debris resistant, with minimal external features that limit particulate accumulation. A true water seal means no condensation will get inside the fixture. It's easy to clean: the dust-tight, IP66-rated enclosure can withstand high pressure water jets.

Ideal for food and meat processing

The Altor WVLF G2 is bacteria and debris resistant, with minimal external features that limit particulate accumulation. A true water seal means no condensation will get inside the fixture. It's easy to clean: the dust-tight, IP66-rated enclosure can withstand high pressure water jets.

Mounting options

The WVLF G2 features multiple hanging options, including the Flexible Ceiling Mount (FCM), the Rigid Mounting Beam in both stainless steel and zinc-plated variations (RBS and RBZ), and the V-hook (VHK - 2-foot version pictured) for chain or cable mount.

Mounting options

The WVLF G2 features multiple hanging options, including the Flexible Ceiling Mount (FCM), the Rigid Mounting Beam in both stainless steel and zinc-plated variations (RBS and RBZ), and the V-hook (VHK - 2-foot version pictured) for chain or cable mount.